Understanding and Caring for Wraps

My Wrap Has a Hole in it- Is This a Catastrophe?!

Discovering that your woven wrap has a hole in it can feel catastrophic, and you may fear that it is no longer safe to use. Before you panic, read our assessment guide through, because in many cases the situation will not be as bad as you think, and your wrap might not actually need to be consigned to the shelf forever!

There are 3 main courses of action that you will need to choose from

- leaving the hole and doing nothing (in many circumstances this is completely fine to do).

- mending or securing the hole in some way (in many instances this is more for cosmetic appeal and practicality than for safety).

- Retire the wrap from use completely.

Once you’ve read our guide, it should be clearer which route will be best for you, and we can show you what to do next!

Assessing the Hole in Your Wrap

How Did it Happen?

How the hole occurred can give a really good indicator of the future safety of the wrap. You can split all incidents in to two categories- holes that occurred due to an incident, and holes that appeared over time.

Holes that appeared without any obvious cause or accident have the worst prognosis overall, because they indicate that there is underlying damage to the threads themselves that is causing them to weaken and wear away. It is usually the weft threads that wear out or become brittle over many years of use, especially if they’ve been washed harshly or have a high linen/hemp content. Occasionally we see instances where contact with strong chemicals has disintegrated the fibres of a wrap, and those would fall into this category too.

Warp threads are much stronger and more durable, so they tend to stay intact, but the weft threads crumble and a hole slowly appears, in much the same way as one might appear in the knees of your jeans. Even when the weft threads start to give way, the warp should stop the cloth from tearing right through, so you aren’t looking at an immediate risk to your baby falling out of the wrap in any way, but chances are that more holes will start to appear in high wear areas, and if you want to keep the wrap cloth to turn into keepsakes or other non-weight bearing items, then now would be the time to retire the wrap, before it gets too damaged to be used for any other purpose.

Perma-creasing can eventually lead to holes along the rails of a wrap. This is where repeated creasing in the same spot on the cloth causes the warp threads to bunch together in places, and create a thinned area that appears to be a hole. You can move the threads back in place, but it will take repeated efforts to move them and fix them back in their original spot in order to close the bare patch. If the weft threads remain exposed without the warp to cover them, they could potentially wear into a true hole over time. This is worth catching early and sorting (or preventing). We’ve written about perma-creasing here.

Holes that appear due to a specific moment of trauma are far less of a worry because the damage is confined to that small area, and the rest of the wrap should therefore be fine.

Quite often, holes can be caused by poking a finger (or similar pointy object) through the weave during wrapping- especially at that point where you’re pulling the wrap up taut against the whole weight of your child, possibly through a single finger rather than spreading the pressure through your whole hand. This concentrates all the force through a single point on the wrap, and the threads part ways to create the path of least resistance. In many cases these threads are displaced to create the hole, rather than broken in any way, and so they just need to be moved back in place.

Other accidental damage is more likely to tear and snap threads when creating a hole. I managed to trap my wrap in the car door when we were coming home from the hospital with my 3rd baby, and the lock mechanism tore a big hole in the wrap! We’re constantly reminding people that broken or snapped threads aren’t actually unsafe in their own right- woven cloth doesn’t start to unravel like knitted fabric does, so, unlike your favourite sweater, a small hole in a wrap isn’t going to get larger or worse over time unless it experiences more direct trauma.

What to do with holes created by damage to the cloth really depends on some more factors listed below.

Where is the hole?

Holes on the tails of a wrap are far less of a complication than ones that occur in the central part of the wrap, which is the area that sees the most action during use. A hole right in the spot that you have to grab the wrap to tighten is going to benefit from fixed more than one in a more ‘passive’ spot.

How Big is the Hole?

Realistically a hole needs to be enormous for it to compromise the safety of the wrap or stop it functioning properly, but holes generally don’t look that pretty, so generally you’d be fixing it for cosmetic reasons rather than safety. A very tiny hole isn’t going to grow bigger unless it sustains more damage, so it might actually be more inconspicuous to leave it alone rather than go messing with it and potentially disturbing the surrounding cloth which would it more obvious. You might want to fix larger holes to make them look better cosmetically, or deter small fingers from making them bigger, prevent the hole from getting caught on something and ripping further etc.

Which Threads Are Involved?

There are hundreds of fine warp threads packed into a small space, they are more dispensable without causing any major visible difference to the cloth, and they have a lot of spare slack spread along the wrap that you can utilise to fix holes. Weft threads tend to be thicker, there are fewer of them and they don’t have as much ‘give’ in them- so you can’t pull on them so much to make the thread longer to work with. If only one set of the threads have been damaged- either warp or weft, then that is a simpler fix, because you already have something in place across the hole to weave new threads through. If both warp and weft threads are severed then it is a bigger job, and best to start with the weft threads first. There are fewer of those and they are larger. Once they’re in place across the wrap you can start to weave the warp threadsthrough them

What Should I Do Now?

Having answered the questions above, you should hopefully have a better idea of whether or not you should be using your wrap still, and if so, whether or not to actually try to fix the hole or just leave it be.

Tiny holes can be left alone, with just a little action to tuck away any yarn ends that are poking out, to make them pretty much invisible again. As there is no safety requirement to secure a hole, if it is so tiny that you can only see it under close scrutiny then best to just leave it alone.

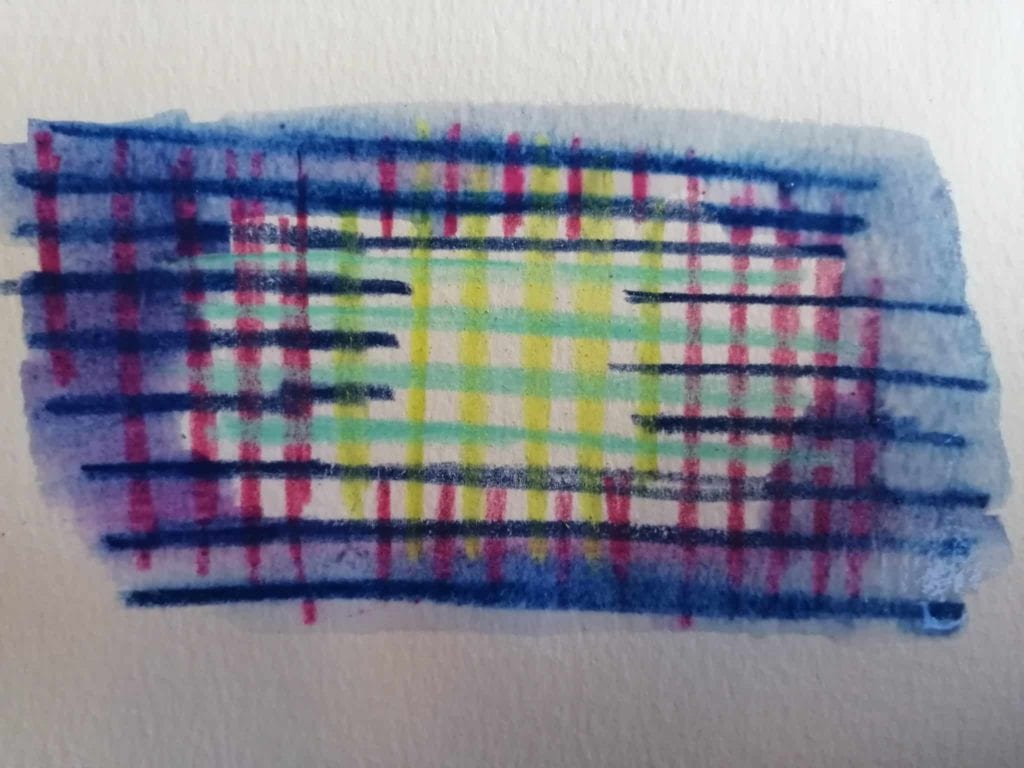

Small holes can easily be fixed by pulling on the affected warp threads to collect some of the slack that is naturally distributed through the wrap (and won’t be missed). You can then use this extra length to weave across the hole and bridge the gap. As broken threads aren’t unsafe in themselves, you don’t need to start knotting anything- that will just create a messy finish and unnatural tension in the cloth. There is less hidden slack to pull through from the weft threads, but hopefully enough to cover a small hole with a bit of overlap. You are looking to fill over the existing space with threads, rather than close up the hole by sewing it together. This video shows you how to do this. Note: the masking tape on the clot in the video is just to help you see what I’m doing- you don’t need to put tape on your own wrap!

for much larger holes you might need to introduce some new threads, either in a similar colour, or contrasting if you’re going to make a feature of it. Again, all you’d be doing is weaving in some new threads into one side of the cloth, then using them to span the hole and weaving them through the other side to hold them in place. You’d want to do that following the direction of both the warp and weft. This is going to be more tricky to mend in an invisible manner, so it might be worth embracing the history of the wrap, and mending it with colourful thread that celebrates it’s eventful journey during use! Try to keep the threads running parallel with the warp and weft, site the new thread an inch or so into the cloth before the hole starts, and carry on past the other side of the hole for another inch, then the yarn is held in place.

Here’s our blog post about mending a large hole in a woven wrap.

These threads are only being floated into the cloth- you don’t need to knot them in at all. Embroidery cotton is usually easy to match up in terms of colour. If you desperately want to use the existing warp/weft then you can try to pull a thread from one of the hems, where it will be less visibly missed.

The simplicity of wrap construction does make them fairly durable, and unlike carriers with weight bearing stitching or plastic buckles, there isn’t much you can do to render them completely useless, so hopefully you are feeling less anxious about the whole hole situation!

A Few Don’ts…

- Don’t knot anything- woven cloth doesn’t unravel the way your favourite knitted sweater would if you left a hole in that. Knots create tension and look messy

- Don’t sew up holes to close them, or patch with other pieces of fabric. The stitched area will be a source of tension, won’t move freely with the cloth when it is stretched, and is more likely to rip as a result.

- Don’t worry! If you aren’t sure what to do next, feel free to email us with photos or a small video, and we’ll talk you through what to do.